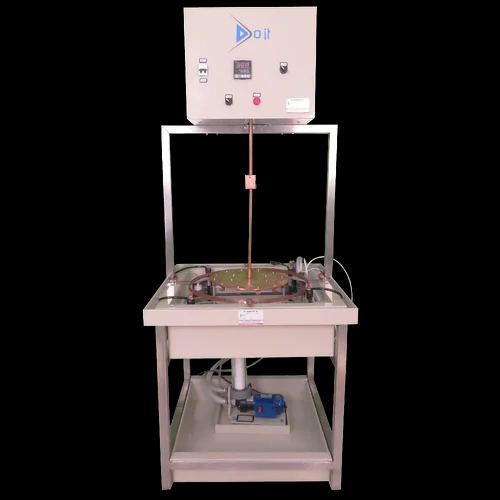

Plating Plant SS Body 5ltr ( Combo offer)

Product Details:

- Frequency 50/6 Hetrz (Hz)

- Cooling System Air Cooling

- Noise Level low db

- Machine Type industrial cleaner

- Voltage 220/ 415 Volt(v)

- Features Heavy Duty

- Frame Type Metal Frame

- Click to View more

Plating Plant SS Body 5ltr ( Combo offer) Price And Quantity

- 1 Unit

Plating Plant SS Body 5ltr ( Combo offer) Product Specifications

- yes

- Heavy Duty

- Plating Plant

- Metal Frame

- industrial cleaner

- 220/ 415 Volt(v)

- Automatic

- Industrial

- Electricity

- low db

- Silver

- 50/6 Hetrz (Hz)

- Air Cooling

Plating Plant SS Body 5ltr ( Combo offer) Trade Information

- 10 Days

Product Description

Gold plating is the process in which a fine gold layer is coated over another metal by an electrochemical reaction. During the electrochemical reaction a DC current gold ions from the gold bath solution is adhered on to the negatively charged piece or article. Gold as itself is ductile and malleable. For enhancing the properties of the articles, materials like Silver, Copper and Nickel are introduced and gold plating is done of it to mimic the same appearance of gold Plant equipped with 2 beakers, separately powered for heating, with adjusting voltage from the potentiometer on the command panel with electronic protection and 2 magnetic stirrer motor to stirr the solution properly in beaker. The machine includes S.S. anodes for degreasing or Gold and Oxal anode for Rhodium. The plant is a multi purpose equipment which can replace more machines, saving space and cost. A single machine to replace other machine to carry out processes like Degreasing, Plating, Antitarnishing, and various other that requires DC current. It is best suitable for any Flash Gold / Rhodium bath.

Features: -

Capacity: 5 Litres

Chemicals & Accessories for 5ltr Plating plant combo includes:

CCCV (Constant Current Constant Voltage) Rectifier with 12V-10 A Borosilicate glass beakers of 5 ltr capacity

Equipped with borosilicate

Glass beaker of 5ltr Capacity

Digital display for voltage and current

Voltage adjustment through potentiometer

Magnetic stirrer for beaker to stirr the solutionTimer Controller to set process time upto 999 Seconds

Temperature controlling regulator for adjusting temperature of beaker.

Provides Steady Voltage that gives desired result in the chemical processes being carried

Terminals provided with easy access, that can accomodate Pin type, Ring or Fork type connectors simultaneously as and when required

FAQs of Plating Plant SS Body 5ltr ( Combo offer):

Q: What is the power source of Plating Plant SS Body 5ltr (Combo offer)?

A: The power source of Plating Plant SS Body 5ltr (Combo offer) is electricity.Q: What is the color of Plating Plant SS Body 5ltr (Combo offer)?

A: The color of Plating Plant SS Body 5ltr (Combo offer) is silver.Q: What is the warranty period of Plating Plant SS Body 5ltr (Combo offer)?

A: Plating Plant SS Body 5ltr (Combo offer) comes with a warranty.Q: What is the operating type of Plating Plant SS Body 5ltr (Combo offer)?

A: The operating type of Plating Plant SS Body 5ltr (Combo offer) is Automatic.Q: What are the applications for the Plating Plant SS Body 5ltr (Combo offer)?

A: The Plating Plant SS Body 5ltr (Combo offer) is used in industrial applications.Other Products in 'Plating Plant' category

|

|

|

|

DOIT INDUSTRIES INDIA PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS